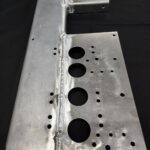

Laser Cutting, CNC Forming, and Precision Sheet Metal Manufacturing and Fabrication Services

At Yama Manufacturing, we offer complete, start-to-finish, sheet metal manufacturing solutions. Whether you seek a reliable and experienced manufacturer to build sheet metal parts from your prints or from 2D/3D CAD models, require assistance with engineering design for manufacturing, or could use some help with prototyping or conceptual and detailed engineering development and documentation, you can rely on us to deliver every time.

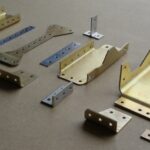

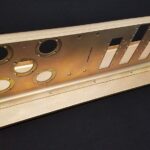

We are a one-stop shop with a wide range of capabilities to manufacture your sheet metal parts from start to finish. We routinely source and purchase raw materials, precisely cut and form parts, manage all secondary (outside) processes such as heat treating, nondestructive testing, plating, etc., and assemble and finish parts.

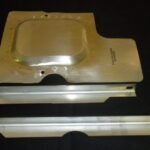

If required, we assemble individual parts to build complete assemblies according to military or commercial standards. We often weld, bond, install rivets, fasteners, and/or all required hardware. Additionally, most parts require some protective layers such as primer and paint. We perform these finish processes in-house. Once complete, we mark parts using various methods and as required, including laser marking, laser engraving, CNC engraving, ink and steel stamping or chemical etching.

We perform all in-process and final quality control and inspections to make certain your parts are made according to your strict requirements. Finally, we package the parts as required, according to either general commercial, or strict military or customer requirements. Our dedicated team of professionals is prepared to manufacture your precision sheet metal parts from start to end or perform only the processes you require.

In-House Services

Value-Added Services

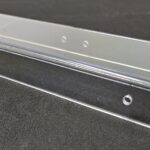

Our in-house sheet metal operations include but are not limited to:

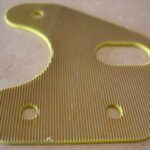

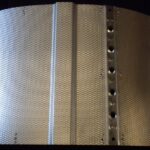

- Laser cutting

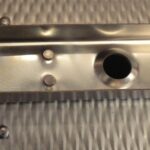

- CNC Press brake bending/forming

- CNC & manual machining

- CNC & laser engraving

- Tool & die design, build, and forming

- 3D solid model development

- 2D CAD and engineering drawing development

- Flat pattern layout development

- Shearing, sawing, and routing, notching, and rolling

- Spot welding, TIG, MIG, and arc welding

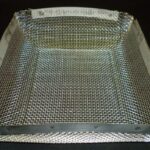

- Assembling sheet metal parts

- Adhesive bonding, riveting, fastening, and installing various hardware

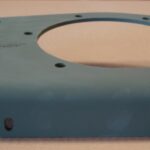

- Priming and Painting

- Park marking (laser, ink & stamp, chemical etch)

- Packaging and shipping

The following processes may be performed through our high-quality, experienced, and certified vendors to provide complete sheet metal manufacturing services to our customers:

- Water jet cutting

- Certified welding

- Stamping

- Chemical milling

- Heat treating

- Plating

- Nondestructive inspection and testing